𝙉𝙤𝙩 𝙖𝙡𝙡 𝙙𝙤𝙬𝙣 𝙟𝙖𝙘𝙠𝙚𝙩𝙨 𝙖𝙧𝙚 𝙗𝙪𝙞𝙡𝙩 𝙩𝙝𝙚 𝙨𝙖𝙢𝙚. 𝙇𝙚𝙩’𝙨 𝙩𝙖𝙡𝙠 𝙗𝙖𝙛𝙛𝙡𝙚 𝙘𝙤𝙣𝙨𝙩𝙧𝙪𝙘𝙩𝙞𝙤𝙣 — 𝙖𝙣𝙙 𝙬𝙝𝙮 𝙞𝙩 𝙢𝙖𝙩𝙩𝙚𝙧𝙨.

In down insulated apparel, the way you contain the down is just as important as the fill itself. You want to ensure maximum lofting of the down for thermal efficiency and warmth.

Here are the 3 most common baffle constructions — each with tradeoffs in warmth, weight, and cost.

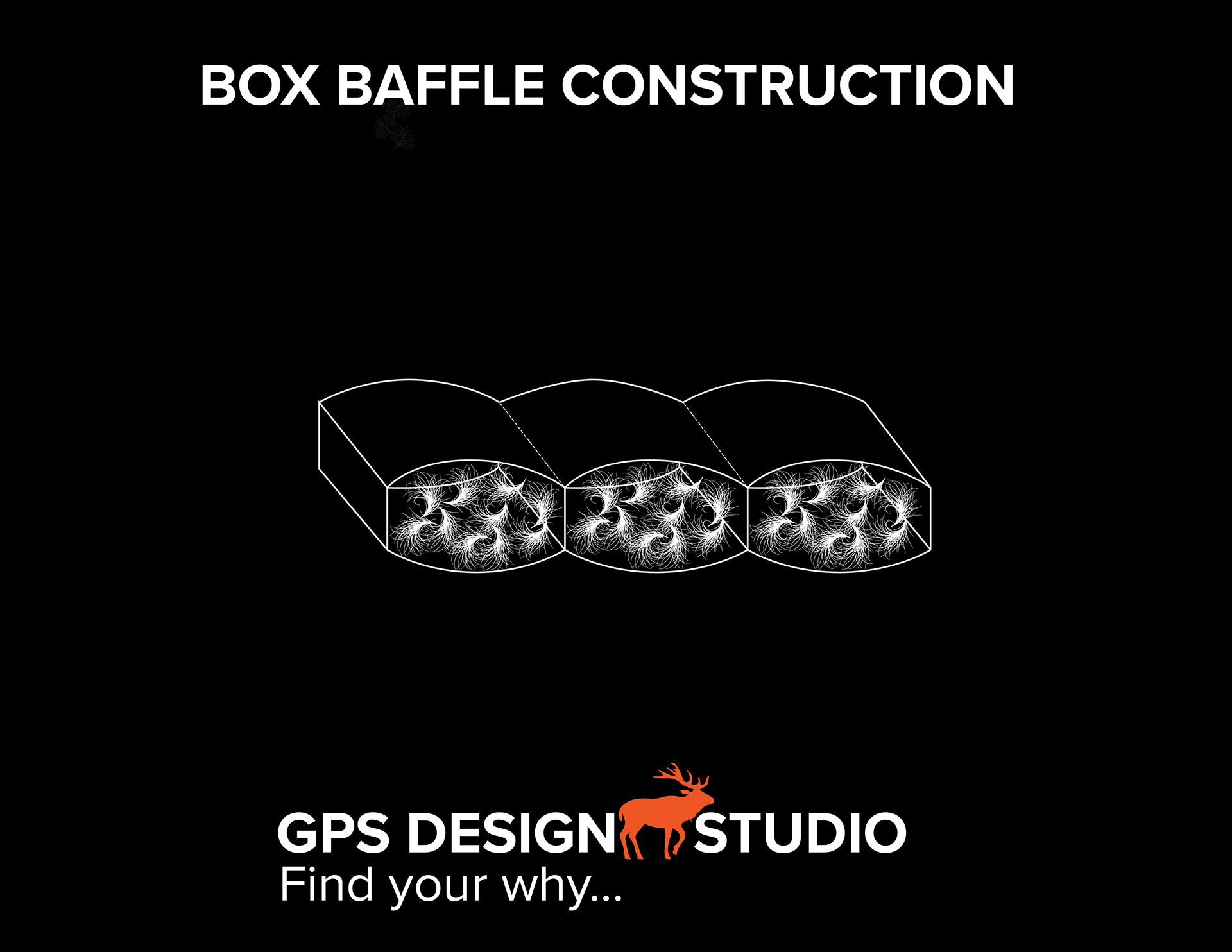

✅ Box Baffle Construction

The gold standard for maximum loft and warmth.

Box baffles use internal fabric walls to create true 3D chambers, allowing down to fully loft without cold spots. Baffle widths can be varied depending on what your end use is.

✔️ Pros: Best thermal efficiency

✖️ Cons: Heavier, more complex, higher cost

🔍 Used in expedition parkas or high-end belay jackets, also premium lighter

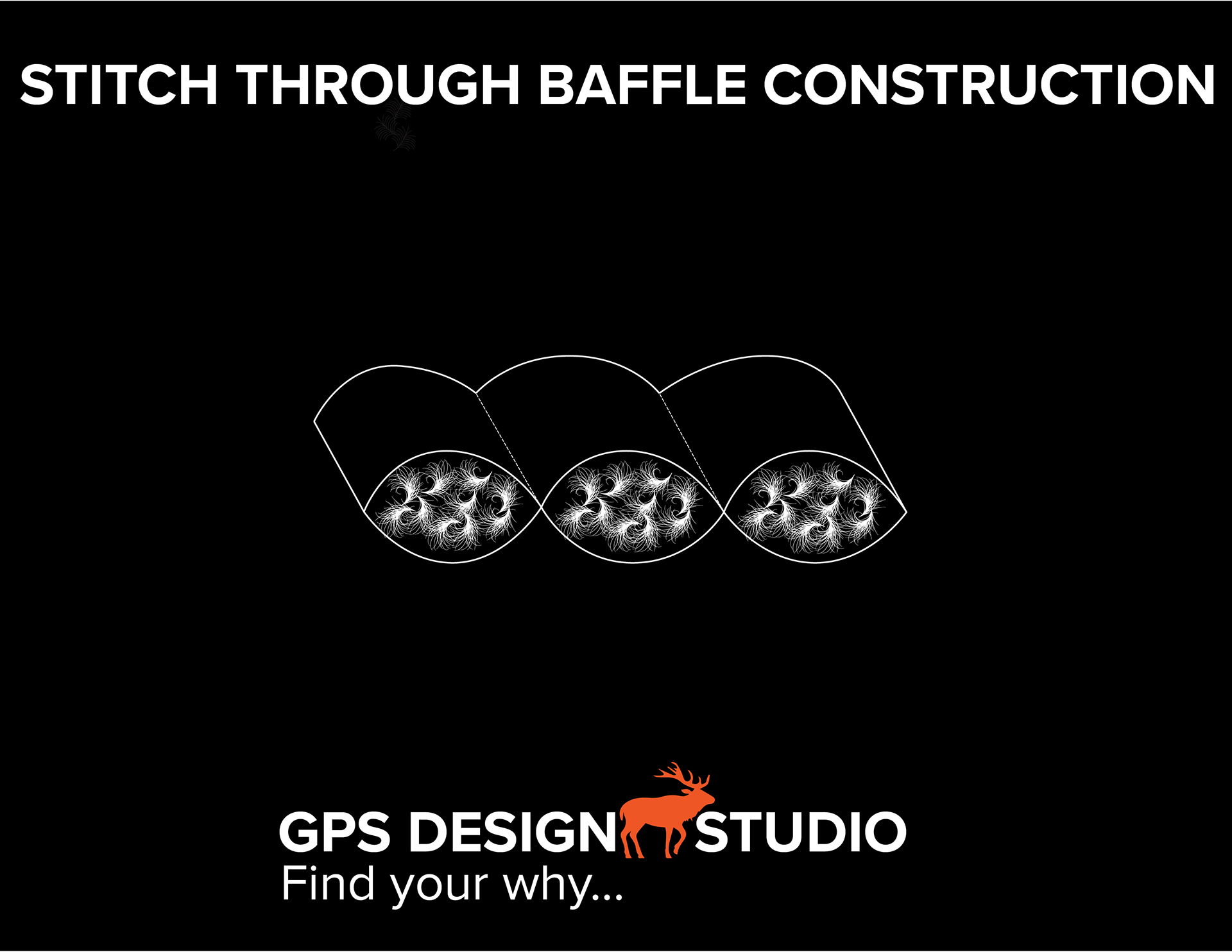

✅ Stitch-Through Construction

The most common and lightweight option.

The shell and liner are stitched directly together to create the baffles, which is simple and efficient — but creates cold seams where insulation is compressed.

✔️ Pros: Lightweight, packable, affordable

✖️ Cons: Less warmth due to cold spots

🔍 Ideal for active insulation or mild conditions

✅ Offset (Double Layer) Baffle Construction

A clever hybrid that staggers the stitch lines between shell and liner, reducing direct cold spots.

✔️ Pros: Better thermal performance than stitch-through, lighter than box baffle

✖️ Cons: More sewing complexity, slightly bulkier

🔍 Often used in mid-weight jackets aiming for warmth without bulk

Whether you're designing for alpine extremes or ultralight performance, understanding baffle construction is key to dialing in warmth-to-weight ratios.

Curious how to choose the right construction for your next outerwear line? Let’s talk insulation design.

In down insulated apparel, the way you contain the down is just as important as the fill itself. You want to ensure maximum lofting of the down for thermal efficiency and warmth.

Here are the 3 most common baffle constructions — each with tradeoffs in warmth, weight, and cost.

✅ Box Baffle Construction

The gold standard for maximum loft and warmth.

Box baffles use internal fabric walls to create true 3D chambers, allowing down to fully loft without cold spots. Baffle widths can be varied depending on what your end use is.

✔️ Pros: Best thermal efficiency

✖️ Cons: Heavier, more complex, higher cost

🔍 Used in expedition parkas or high-end belay jackets, also premium lighter

✅ Stitch-Through Construction

The most common and lightweight option.

The shell and liner are stitched directly together to create the baffles, which is simple and efficient — but creates cold seams where insulation is compressed.

✔️ Pros: Lightweight, packable, affordable

✖️ Cons: Less warmth due to cold spots

🔍 Ideal for active insulation or mild conditions

✅ Offset (Double Layer) Baffle Construction

A clever hybrid that staggers the stitch lines between shell and liner, reducing direct cold spots.

✔️ Pros: Better thermal performance than stitch-through, lighter than box baffle

✖️ Cons: More sewing complexity, slightly bulkier

🔍 Often used in mid-weight jackets aiming for warmth without bulk

Whether you're designing for alpine extremes or ultralight performance, understanding baffle construction is key to dialing in warmth-to-weight ratios.

Curious how to choose the right construction for your next outerwear line? Let’s talk insulation design.